Select which  control family:

control family:

60’s – 80’s

80’s black

80’s – 90’s

90’s – 00’s

Domino controls (comandi) are made in Italy since the 1950’s. Domino controls are found on most Italian mopeds, such as Arciero, Aspes, Baretta/Piccoli, Beta, Bianchi, Cimatti, Concord/Fantic, Demm, Gadabout, Garelli, Malaguti, Motobecane Sebring, Motomarina, Motron, Negrini, Pacer/Italtelai, Snark, late 80’s Tomos, and Vespa/Piaggio. Other Italian mopeds had PV, OSL, or Ci.Ti controls. Domino has made, and still does make, many other high quality motorcycle controls.

MMI Part Numbers: In 1982 the biggest USA moped part importer/distributor Marina Mobili Inc assigned Domino part numbers that began with “D”. The “D” parts were for sale to the public through all moped dealers.

MM Part Numbers: Domino also made controls specifically for Vespa and Garelli. Those parts were only sold through Vespa or Garelli dealers. They never did have a MMI part number. Myrons Mopeds made up the “V” and “G” part numbers to agree with the corresponding “D” part numbers used by MMI.

Brake light switch holes: Many non-US models do not have brake lights. So their Domino housings don’t have threaded holes for brake light switches. Their Domino “70’s chrome” levers do not come with the inner push plate that pushes the button on the brake light switch. Their lever blades do not have the extra little hole punched in them to anchor the inner push plate. Here all of the housings and levers are for US-models with a brake light, unless noted.

Prices: green means new. dark green means used, n.a. means not available. Used items are cleaned, lubed, checked and in good or usable condition unless stated otherwise. Control assembly prices do not include hand grips or electrical switches, unless stated otherwise.

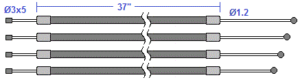

Mostly slide type throttles: Most of the throttles shown here are the sliding block (cursor) type, where the twist tube (barrel) has a spiral slot that moves a sliding block back and forth. The sliding block contains a set screw that secures the throttle cable inner wire. The throttle cable exits parallel to the handlebar. The advantage of slide type throttles is they use a single ended universal-type throttle cable that is easy to get and replace. The disadvantage is they can’t pull the cable very far, so they are only used on very small carburetors like mopeds and mini-cycles have.

Some wrap around throttles: Only some throttles shown here are the wrap around type, where the cable wraps around the twist tube. The throttle cable exits perpendicular to the handlebar. The advantages of wrap around type throttles are they stick less and can pull the cable farther. The disadvantage is they require a double ended throttle cable, which is specific to the carburetor and the cable pipes.

These throttles need occasional lubrication (oil or grease), or they become sticky and eventually wear out. Because the twist tube is steel and the sliding block is aluminum, it’s the sliding block that wears out the most. Even with lubrication, a worn sliding block causes the throttle to stick, where it does not snap back when you let go. After 1978, they had a helper spring on the twist tube. This made them not stick as much, or not at all.

Twist Tubes (throttle barrels): Domino made improvements to the twist tube and slider every 10-15 years. In the 1960’s and early 70’s the D6 and D6L steel twist tubes used a D1 slider and had no assist spring flange. In 1978 a throttle return assist spring was added. The D6a and D6aL steel twist tubes had a flange with a spring anchor slot. The part where it goes inside the housing was longer. At first only deluxe models had an assist spring, but by the 1980’s all moped models did. In the 1980’s a new family of all-black controls came out, with built-in (integrated) switches. The twist tube retaining screw had to be relocated to make room for the switches. It was moved from the top near the grip to the bottom near the clamp bolt. D6B and D6BL steel twist tubes had slots for both the new and old retaining screw locations. Also in the 1980’s the twist tube changed from steel to non-stick plastic, and slider changed from D1 to D1K. There were two versions D6N and D6NL with no assist spring, and two versions made for an assist spring D6K ands D6KL. Understanding the twist tube is the key to understanding the control families.

Domino, MMI and MM Part #’s

Domino, Marina Mobili Inc. (MMI) 1980’s, and Myrons Mopeds (MM) 2020’s.

Domino# MMI# MM# all levers have ball ends

0300.03 0000 DA0 silver plain bl ribbed

0000.00 DA1 DA1 silver plain bl waffle

0000.00 D5 D5 00 housing xx bl

0000.00 0000 DB0 silver plain bl ribbed

0000.00 DB1 DB1 silver plain bl waffle

0000.00 D18 D18 0 housing xx bl

0000.00 0000 VA1 silver plain bl ribbed

0431.03 0000 VA1 silver plain no bl ribbed

0000.00 0000 V5 00 housing xx bl

0000.00 0000 VB1 silver plain bl ribbed

0199.06 0000 VB1 silver plain no bl ribbed

0000.00 0000 V18 0 housing xx bl

0000.00 0000 DA0d silver diam bl ribbed

0286.03 0000 DA0d silver diam no bl ribbed

0000.00 0000 D5d 0 housing xx bl

0000.00 0000 DB0d silver diam bl ribbed

0000.00 0000 DB0d silver diam no bl ribbed

0000.00 0000 D18d 0housing xx bl

0000.00 DA1A DA1b black plain bl

0000.00 D5A D5b black plain bl

0000.00 DB1A DB1b black plain bl

0000.00 D18A D18b black plain bl

0000.00 DA3B DA1db black diam bl

0000.00 D5B D5db

0000.00 DB3B DB1db black diam bl

0000.00 D18B D18db

0000.00 DA3 DA2 silver plain bl assist

0000.00 0000 D5a

0000.00 DB3 DB2 silver plain bl

0000.00 D18 D18

0000.00 DA4B DA2b black plain bl assist

0000.00 0000 D5ab

0000.00 DB4B DB2b black plain bl

0000.00 0000 D18b

0000.00 0000 DA3b black diam bl assist

0000.00 D5C D5adb

0651.06 0000 DB3b black diam bl

0000.00 D18C D18db

0000.00 DA3M DA3m black diam bl assist

0000.00 D5C D5adb long lever

0000.00 DB3M DB3m black diam bl

0000.00 D18C D18db long lever

Garelli and MM Part #’s

page 10 ’77 Sport

01 506851.0142 L control gB1 silver plain no-ball lever

03 506851.0131 R control gA1 silver plain no-ball lever

32 506351.5212 L housing G18 silver plain

page 10 ’77-78 Sport

01 506852.0142 L control GB1d silver diamond

03 506852.0131 R control GA1d silver diamond

32 506852.5212 L housing G18d silver diamond

page 21 ’77 Gran Sport

page 34 ’77 Super Sport

01 506901.0142 L control GB1 silver plain

03 506901.0131 R control GA1 silver plain

32 506351.5212 L housing G18 silver plain

page 65 ’76-78 Gulp

00 506901.0142 L control GB1 silver plain

00 506901.0131 R control GA1 silver plain

02 506351.5212 L housing G18 silver plain

page 80 ’76-77 Eureka

page 95 ’75-76 Eureka

00 506351.0142 L control GB1 silver plain early grip

00 506351.0131 R control GA1 silver plain early grip

02 506351.5212 L housing G18 silver plain

After late-77 all throttle controls had an assist spring.

page 21 ’77-79 Gran Sport, Ltd, Rally Sport

page 34 ’77-79 Super Sport, Ltd

01 506903.0142 L control GB2d silver diamond

03 507251.0131 R control GA2d silv diam assist

32 506852.5212 L housing G18d silver diamond

page 50 ’77-79 VIP

01 506903.0142 L control GB2d silver diamond

03 507251.0131 R control GA2d silv diam assist

32 506852.5212 L housing G18d silver diamond

page 141 ’80-82 VIP

36 506903.0142 L control GB2d silver diamond

37 507251.0131 R control GA2d silv diam assist

After ’81 all controls were black with longer levers and grips.

page 115/1 ’80-83 Sport, Rally Sport, Ltd, 2sp

31 507991.0142 L control GB3m black diamond

32 507991.0131 R control GA3m blk diam assist

page 126/1 ’80-83 Super Sport XL, Ltd, Ltd 2sp

31 507991.0142 L control GB3m black diamond

32 507991.0131 R control GA3m blk diam assist

page 154 ’83-84 Monza GT

30 507991.0142 L control GB3m black diamond

31 507991.0131 R control GA3m blk diam assist

1978 Domino Catalog

Domino part#: black is in 1978 Catalog, red is an add-on

ba = brake adjuster, ta = throttle adjuster, sa = start adjuster

bl = brake light, hb = horn button, bh = holes for switch base

oval = oval-diamond switch base, rect = rectangular switch base

rg = Normale (ribbed grip) 105 black

rg = Normale (ribbed grip) 105 grey

wg = America (waffle grip) 105 black

lg = America (long waffle) 120 black

tg = Motocross (texture grip) 120 black

tg = Motocross (texture grip) 120 gum

. no bl x no bl with bl Right Control 140

chrome nylon chrome < 140 lever ball-end, 105 grip

181.03 800.03 300.03 slide 20mm cable pull, Turismo

286?03 802.03 000.03 slide rg oval

431.03 818.03 000.03 slide rg ba

207.03 825.03 000.03 slide rg ba, oval

287.03 824.03 000.03 slide rg ta, oval Garelli

198.03 000.00 000.03 slide rg ba, hb Piaggio

195.03 000.00 000.03 slide rg, thumb lever

484.03 000.00 000.03 slide rg, rect

530.03 823.03 000.03 slide rg ta, Garelli

433.03 813.03 000.03 wrap rg, 25mm cable pull, Sport

412.03 000.00 000.03 wrap rg, thumb lever

. no bl x no bl with bl Right Control 155

chrome alum. alum. < 155 lever ball-end, 120 grip

000.03 392.03 000.03 slide tg assist ba ta, Jr, oval

378.03 000.03 000.03 slide tg assist ba ta, Std, oval

000.03 348.03 000.03 slide tg assist ba ta, Jr

377.03 000.03 000.03 slide tg assist ba ta, Std

000.03 291.03 000.03 wrap tg ba, Junior

349.03 000.03 000.03 wrap tg ba, Standard

000.04 304.04 000.04 R lev tg ba Junior

338.04 000.04 000.04 R lev tg ba Standard

. no bl x no bl with bl Left Control 140

chrome nylon chrome < 140 lever ball-end, 105 grip

288.06 801.06 000.06 2 lev rg 140 Minarelli

352?06 814.06 000.06 2 lev rg 115 Morini

447.06 000.00 000.06 2 lev rg 70 Puch

295?06 815.06 000.06 2 lev rg 115 sa Garelli

199.06 000.00 000.06 2 lev rg 70 ba Piaggio

446.06 000.00 000.06 2 lev rg 70 ba oval

350.06 000.00 000.06 2 lev rg 115 ba sa

500.06 803.06 000.06 2 lev rg 140 sa Garelli

297.06 000.00 000.06 2 lev rg 100 ba Benelli

510.06 000.00 000.06 2 lev rg 100

472.06 000.00 000.06 2 lev rg 115 ba oval, black

000.06 000.00 651.06 2 lev wg 115 oval, black

489.06 825.06 000.06 2 lev rg 115 ba

186.04 805.04 000.04 L lev rg

198.04 000.04 000.04 L lev rg ba Benelli

432.04 819.04 000.04 L lev rg ba

434.04 000.04 000.04 L lev rg ba, decomp

445.04 000.04 000.04 L lev rg ba oval, black

. no bl x no bl with bl Left Control 155

chrome alum. alum. < 155 lever ball-end, 120 grip

000.04 295.04 000.04 L lev tg ba Jr

376.04 000.04 000.04 L lev tg ba Std

000.04 347.04 000.04 L lev lg ba Jr

332.04 000.04 000.04 L lev lg ba Std

000.04 310.04 000.04 L lev lg ba bh Jr

218.04 000.04 000.04 L lev lg ba bh Std