Welcome. The photos and info below are from:

1) 1976 ND Spark Plugs Service Manual

The info is for pre-1977 four-stroke engines, mostly cars.

2) 1979 Haynes Honda Express Manual

Dark blue text is quoted from the manual. Dark green text is Myrons.

The condition of the spark plug indicates both engine condition and combustion products. A new car with an unworn engine would soon have black spark plugs if a little oil or diesel fuel was added to the gas tank. The combustion of oil produces tar or soot. An old car with a worn engine might also have the same black spark plugs. The tar or soot in that case is partly from the combustion of oil that leaked past worn rings, cylinder walls and valve guides, and partly from low compression. Low compression then has many possible causes. So a spark plug analysis does not tell exactly what is wrong or right in one step. Other evidence is needed in order to make a conclusion or diagnosis.

1) 1976 ND Spark Plugs Service Manual

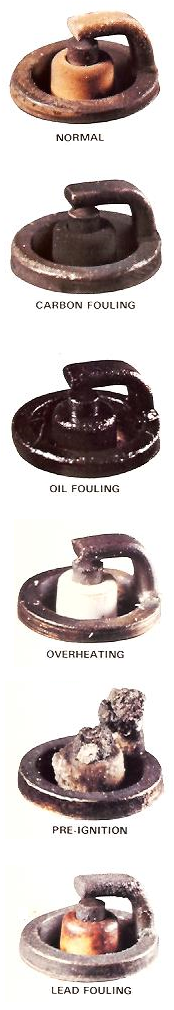

NORMAL

Light grey or tan deposits indicate proper heat range.

On mopeds this indicates a clean and proper combustion process. That means quality gasoline and quality two-stroke oil are mixed correctly and are free from dissolved contaminants such as tar. Also the engine is healthy and is operated normally.

The white porcelain insulator of a new spark plug takes awhile to became tan colored, about 50 miles.

CARBON FOULING

Dry sooty black deposits result from over rich carburetion, sticking choke, clogged air filter, poor ignition circuit, continuous low speed operation or heat range too cold. Carbon fouling is mostly affected by the air-fuel ratio. The richer the charge is, the more the spark plugs are apt to be carbon fouled. When only one spark plug in a group is carbon fouled, it is probably due to a poor ignition circuit or poor compression.

On mopeds, carbon fouling is caused by, most frequently first, stale old gasoline, fresh gasoline containing dissolved tar from a tarry gas tank, low compression, continuous low speed operation, spark plug heat range too cold, or a rich air-fuel mixture.

OIL FOULING

Wet oily deposits are usually caused by oil leaking through worn piston rings or valve guides, or engine still in “break-in” period. Oil fouling may also be caused by poor carburetion or over rich mixture.

Spark plugs cannot solve this trouble fundamentally. An engine overhaul may be necessary to correct this condition. Hotter spark plugs might help oil fouling.

On mopeds, oil fouling is caused by, most frequently first, too much two-stroke oil mixed in the gasoline, clogged exhaust, continuous low speed operation, poor quality two-stroke oil, spark plug heat range too cold, rich air-fuel mixture, or non-two-stroke oil mixed in the gasoline.

OVERHEATING

Blistered white insulator and excessively eroded electrodes are usually signs of overheating. Spark plug overheating may result from improper tightening (too loose), clogged cooling system, or improper heat range (too hot).

The overheated spark plugs will ignite the fuel-air mixture prematurely before sparking takes place across the plug gap (pre-ignition). When pre-ignition becomes really bad, the prematurely ignited charge may pop through the open inlet valve, thus producing no power but overheating the valves and other parts, which eventually are severely damaged.

PRE-IGNITION

On mopeds (and cars), pre-ignition (pinging) is caused by the compression ratio being too high for the octane rating of the gasoline being used. It is also caused by an overheated spark plug. Occasional light pinging is not bad, but constant or heavy pinging causes damage. The ping explosions carve out tiny craters in the top of the piston. The molten aluminum mist then coats the spark plug insulator silvery, and also the cylinder wall. Both spark plug electrodes erode from the ping explosions. The one shown is extremely bad.

LEAD FOULING

The lead compound and associated additives reduce pinging or knocking (pre-ignition) and help promote long valve life. But since the 1980’s lead has been banned from use in gasoline. It was found to be poisonous and to cause brain damage, especially a young child repeatedly standing next to a running car or school bus exhaust. This info about lead fouling and lead additives is from 1976 before the days of unleaded gas.

You may have experienced hesitation just after steep acceleration with the spark plugs used for a few thousand miles. There are counted many causes, but if the spark plugs have powdery or granular deposits around the insulator tip and/or at the end of the insulator tip, the hesitation is due to lead fouling.

Most of the fuels used in automobiles contain tetraethyl lead additives to improve anti-knock quality. And at the same time a halogenide is added, which helps lead compounds from combustion of such fuels to gasify easily and be emitted through the exhaust system. Furthermore phosphorous additives are mixed in the fuels to prevent the troubles of lead fouling.

But when the temperature at the insulator tip is low, halogenide lead in gaseous state accumulates on the insulator tip. This accounts for the fact that under city driving, the accumulation of lead deposits occurs more frequently.

Such a coating on the insulator tip remains nonconductive when cold, though at high temperatures (high speed driving) it becomes conductive and provides a leakage path for the high voltage current, which eventually weakens the ignition sparks or even causes misfiring.

2) 1979 Haynes Honda Express Manual

Checking the plug gap with a feeler gauge.

.

.

Altering the plug gap. Note use of correct tool. A small screwdriver can also be used to pry open the gap as long as it does not push against the center electrode. Instead it pushes against the outer shell.

.

NORMAL

Brown, tan or gray firing end is indicative of correct engine running conditions and the selection of the correct heat rating plug.

.

CARBON FOULING

Black sooty deposits indicate an over-rich fuel-air mixture, or a malfunctioning ignition system. If no improvement is obtained, try one grade hotter plug.

.

OVERHEATING

A blistered white insulator or melted electrode indicates over-advanced ignition timing or a malfunctioning cooling system. If correction does not prove effective, try a colder grade plug.

.

BURNT OIL

White deposits have accumulated from excessive amounts of oil in the combustion chamber or through the use of low quality oil. Remove deposits or a hot spot may form.

.

OIL FOULING

Wet, oily carbon deposits form an electrical leakage path along the insulator nose, resulting in misfire. The cause may be badly worn engine or a malfunctioning ignition system.

.

WORN OUT

A worn spark plug not only wastes fuel but also overloads the whole ignition system because the increased gap requires higher voltage to initiate the spark. The condition can also affect air pollution.