Contents:

1. Pinch Bolts (knarps)

2. Ends, Adapters, Misc

3. Adjusters (adjustable stops)

4. Ferrules (cable stops), End Caps

5. Bulk conduit (housing) and Wire

———- partition ———-

6. Cloth cable restoration

1. Pinch Bolts

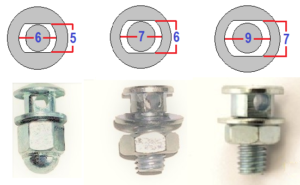

P4-P10: Barrel Pinch Bolts (Knarps)

MM# price dia. len. max

MM# price dia. len. wire part# (length is without bolt)

oP4 $2.00 4.0 9.0 2.0 3548

oP5 $2.00 5.0 7.2 2.0 121-00416 for most throttles

P5a $2.00 5.5 7.5 2.0 3546 for many throttles

P6a $7.00 6.0 11 2.2 good used, MB original

P6b $7.00 6.0 8.0 2.2 good used, Peugeot original, use P6c

P6c $2.00 5.5 10 2.5

oP7 $2.00 7.0 9.0 2.5 3536

P7a $3.00 7.0 9.0 2.5 632876

P7b none 7.0 11 2.5 new, Vespa scooter original

P7c $8.00 7.0 13 2.5 good used, Peugeot original

oP8 $2.00 8.0 8.0 2.8 4906 with plain bolt (shreds easier)

P8a $4.50 8.0 8.0 2.8 49060R with bolt end rounded

P8b $5.00 8.0 13 2.5 620-28020

P8c $2.00 8.0 11 2.5 3538

P8d $2.00 8.0

P8e $3.00 8.0 12 4.0

P8f none 8.0 15 2.5 long enough for hand levers

P8g $5.00 8.0 15 2.5 long enough but no groove or lip

oP9 $4.00 9.0 9.5 3.0

P10 $5.00 9.5 16 2.5 620-28000

Rounded screws: Most pinch bolts have a regular screw end. But some have a domed or rounded end. Those hold better and don ‘t cut the braided wire. The rounded end folds the wire into a curve when the bolt is tightened.

P20: Stepped Pinch Bolts

oP20 $3.00 Ø3.8 x Ø7.0 Peugeot decomp, chrome repro

P20a $5.00 Ø4.3 x Ø7.1 Barnett remake, must grind 4.3 to 3.8

P21-P22: Loop Pinch Bolts

P21 $12.0 6 pieces M7 11 hex good used, Vespa, for ∅11 arch

P22 $7.50 6 pieces M6 10 hex, 74-91 Tomos, for ∅10 hole

P25, P27: Flat-Sided-Hole Pinch Bolts

P27a $2.00 bicycle type Ø6 x 5, M5 thread

P27b $2.00 bicycle big, Ø7 x 6, M6 thread

oP25 $4.00 moped type Ø9 x 7, M6 thread, for Grimeca

P26: Clevis Clamp Pinch Bolts

P26a $17.0 original type for Hercules, AMF & KTM

P26b $10.0 clevis pinch bolt

P26c $4.00 clevis adapter

P26d $13.0 heavy duty for Hercules, AMF & KTM

2. Ends

E1: End Adapters

MM# price 0 part# 0 cable

E1a $2.00 25880 brake ∅6 to ∅8.7 x 8.5

E1b $6.00 Sachs start ∅3 to ∅4∅6 x 13

E1c $2.00 Barnett throt. ∅3 to ∅4.8 x 7.9

E1d $1.50 25349 throt. ∅3 to ∅6.0 x 7.0

E1e $1.50 ooooo throt. ∅3 to ∅5.9 x 4.6

E1e1 $2.00 ooooo brake ∅6 to ∅7.0 x 9.8

E1f $1.80 ooooo brake ∅6 to ∅8.0 x 8.3 side-slot

E1f1 $2.00 ooooo brake ∅6 to ∅8.0 x 10 side-slot

E1g $2.00 ooooo brake ∅5 to ∅8.0 x 10.3

E1g1 $2.00 ooooo brake ∅5 to ∅8.0 x 9.7

E1h $2.00 ooooo brake ∅6 to ∅8.0 x 9.0

E1i $2.00 ooooo brake ∅5 to ∅8.0 x 14.5

E1j $2.00 25063 throt. ∅3 to ∅4.0 x 7.4

E1k $2.00 25049 throt. ∅3 to ∅5.5 x 5.7

E1l $2.00 25062 throt. ∅3 to ∅5.7 x 5.9

E1m $2.00 23420 brake ∅6 to ∅9.0 x 9.0

E2: End Adapters (Anchor Pins)

These are also called holdfasts and socket bolts in some parts catalogs.

Adding a washer: For the ’70’s Domino smaller left lower lever for starting, a washer is added on the replacement, for centering the cable in the hollow lever. When the cable is centered in the lever, it performs the best and does not click or shift around.

E2-DA 00 $0.0 diam length years for lever family

E2-DA 00 $1.80 ∅9.4 09.3 ’02-07 Domino Tomos 221222

E2-DA 00 $0.00 ∅0.0 00.0 ’08-17 TBS Tomos (Domino clone)

E2-D14K $3.00 ∅8.9 12.9 80’s Domino

E2-D14a $8.00 ∅7.9 13.6 70’s Domino start lever

E2-D14b $4.00 ∅7.7 15.7 D14a substitute

E2-D14 x $3.50 ∅7.7 15.7 70’s Domino (or Magura)

E2-AP 00 $4.00 ∅7.8 15.0 70’s-80’s Magura (or Domino)

E2-LA 00 $4.50 ∅7.8 17.9 ’92-08 HR Tomos 227169

E2-D14p none ∅7.8 16.0 70’s Domino (or Magura) slotted pinch bolt

E3: Misc. Cable Items

E3a $1.00 threaded rod nut M6, some cables have a rod end

E3b $4.00 threaded rod barrel, for a threaded rod end

E3c $0.00 elbows (cable pipes) are listed in carburetor parts

E3d $1.00 soft metal crimp on end cap, covers wire ends

E3e $2.00 in line oiler with attached cap, for oiling the cable

E4: Bicycle Ends

Comparison of moped and bicycle cable ends.

E4a pear ∅3.9/6 x 9 use E5s

E4b barrel ∅7.0 x 7.0

E4c inline ∅4.0 x 5.0

These bicycle cable ends are listed here to show how much different they are from motorcycle cable ends. A bicycle gear cable 4mm end could be ground down to become a motorcycle throttle cable 3mm end. A bicycle brake cable road type interchanges with a motorcycle pear or mushroom type. A bicycle brake MTB type 7mm end fits loosely into a 8 or 9mm motorcycle brake lever, but functions OK.

E5: Solder Type Ends

MM# price diameter length hole

E5a $0.50 000 6.0 3.0 1.7

E5b $0.50 000 5.5 3.2 1.7

E5b $0.50 000 6.3 3.3 1.6 620-25162

E5c none O00 4.6 ball 1.7 620-24187

E5d $0.50 000 5.4 ball 1.7 620-24162

E5e $1.00 000 6.3 ball 1.7 620-24062

E5f $1.00 000 3.9 7.2 1.6 620-25063

E5g none 000 4.9 7.4 1.8 000-ooooo

E5h none 000 4.6 10.2 1.4 000-ooooo

E5i $1.00 000 6.0 7.0 1.3 620-25349

E5j $1.00 000 9.5 9.5 2.0 620-25580

E5k $1.50 000 3.0 5.0 1.8 wp70-1012 for carbs

E5l none 000 3.2 3.5 1.7 620-24762

E5m$0.50 3.1/5.2 7.8 2.0

E5n $0.50 3.8/6.0 6.6 2.7

E5p $0.50 4.0/6.3 10.1 2.0

E5q $0.50 3.9/6.3 11.5 2.3 620-26298

E5s none 3.3/5.6 8.1 1.6 620-26162

E5t $2.00 000 8.0 9.0 2.0 wp70-1003

3. Adjusters

A1-A13: Screw-in Adjusters

MM# price 0 thread 0 part# (with nuts unless noted)

A1a $6.00 M5-0.75 219625 for Dellorto elbow

A1b $4.00 M5-0.80 for Puch Bing elbow

A1c $5.00 M5-0.90 023089 for Motobecane

A1d $2.00 M5-1.00 very coarse, for ?

A2a $3.00 M6-1.00 hex no slot

A3a $3.00 M6-1.00 round no slot good used

A3b $5.50 M6-1.00 222592 round slotted orig 90’s Tomos blk

A3c $4.50 M6-1.00 021222 no slot w/star nut orig Motobecane

oA4 $5.00 M6-1.00 hex long used

A5a $4.00 M7-1.00 hex used

A5b $5.00 M7-1.00 round slotted

A6a $5.00 M8-1.25 round slotted

A6b $5.00 M8-1.25 hex slotted short

A10 $4.00 M6-0.75 00189 without nut for Motobecane carb

A11 $4.00 1/4 – 24 aluminum

A12 $7.50 M7-1.00 short for Motobecane decomp

A13 $5.00 M6-0.75 110437 for Dellorto, Bing, Gurtner, and Asian carbs

A1, A7: Adjuster nuts

MM# price 0 thread 0 part#

A1a $3.00 M5-0.75 219626 thin nut for Dellorto elbow

A7a $1.50 M5-0.80 thin nut

A7b $1.50 M6-1.00 thin nut

A7c $3.00 M6-0.75 169227 thin nut hex 7

A7d $2.50 M6-0.75 04172 thin nut hex 9 Motobecane

A7e $1.00 M6-1.00 21157 plastic star nut Motobecane

A8-A9: Non-screw-in Adjusters

oA8 $5.00 in-line, for joining two 5 or 6mm sleeves

A9a $9.00 Magura short, good used

A9b $6.50 Magura long, good used

A9c $5.00 Magura long remake, good used

A9d $9.00 Magura short w/elbow for Kreidler

4. Ferrules

F1-F5: Step Ferrules

MM# price od1 od2 id2 length part#

F1x $3.00 5.9 8.0 5.8 13.0 15581 for MB rear brake, use F1c

F1a $3.00 5.9 8.0 5.4 10.0 43678 for Peug front brk, use F1c

F1c $1.50 4.9 8.0 6.5 12.5 3514 zinc-plated steel, shiny

F2x $2.00 4.0 7.0 5.5 11.0 16944 for Motob. decomp, use F3

F3x $0.70 4.0 7.0 5.5 10.0 zinc-plated steel, photo $3/10

F3x $0.70 4.0 7.0 5.5 10.0 aluminum

F4a $1.00 4.0 7.0 6.0 12.0 aluminum

F4b $2.00 4.5 7.7 5.8 16.7 Barnett

F4c $2.00 5.3 6.8 6.2 19.0 Barnett

F5a $2.00 5.9 11.9 10.4 15.4 Barnett

F5b $0.00 0.0 0.0 0.0 00.0 miscellaneous

F5c $0.50 7.9 12.0 6.0 12.0 bicycle brake universal

The above step ferrules all fit loosely over the cable conduit. The end cap type ferrules below fit tight on the conduit, or are crimped on by special pliers. The end caps are supposed to fit tight, for several reasons: For strength and cable performance, to help keep out dirt and water (thus increasing lifetime), and for easier servicing. Unlike the step ferrules, which are necessary, the end cap ferrules are not necessary. Sometimes conduits need to be cut and the end cap ferrule needs to be left off. The conduit will still function good without end caps, as long as the adjuster or other stop piece hole, usually 2.5mm, is not too big. Without a 6mm OD end cap ferrule, a 5mm conduit will eventually slip through an improper stop piece hole, like 4mm instead of 2.5mm. But as long as the holes in the end pieces are the proper size, the cable does not need end cap ferrules.

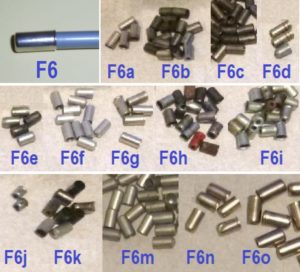

F6: End Caps

MM# price i.d.

F6a $0.50 4.8 with flare, bicycle

F6a $1.00 4.5 with flare

F6b $0.50 4.8 no flare

F6b $0.50 5.1 no flare, Barnett

F6c $0.50 4.8 no flare, Barnett

F6d $0.50 4.0 no flare Shimano SIS

F6e $0.50 4.5 no flare, Sachs

F6f $0.50 5.0 620-20100 no flare, aluminum

F6g $1.00 5.0 with flare, chrome

F6h $1.00 5.1 with flare, used orig on Peugeot, MB

F6i $1.00 5.0 with flare, Puch

F6j $1.00 5.5 with flare

F6k $0.50 6.0 no flare, Barnett

F6m $0.50 5.5 620-20110 no flare, aluminum

F6n none 6.1 with flare, chrome

F6o $1.00 7.1 with flare, chrome, too big for mopeds

![]()

Here is a tapered punch being used to add a flare to a flareless end cap.

5. Bulk Items

B1-B6: Bulk Inner Wire

Sometimes very long cables are needed, for long bikes, or very tall handlebars, or for other things that use mechanical control cables. For 1.2mm and 1.6mm thick inner wires, up to 8 feet, it is better to use bicycle wires. beacuse they already have end(s) and cost less. The same quality 5mm conduit (housing) for bicycles costs much less than for motorcycles, and comes in colors. For thicker or longer cables, the bulk motorcycle wire and black conduit is the only choice.

B1 610-03080 ∅1.2 1×9 $0.80/ft stiff braid (throttle)

B1 610-03080 ∅1.2 1×9 $6.00/8.5 ft WTL w/carb end

B2 610-03090 ∅1.2 7×7 none soft braid (throttle)

B3 610-03100 ∅1.6 1×9 none stiff braid (brake)

B4 610-03110 ∅1.6 7×7 $1.00/ft soft braid (brake)

B4 610-03110 ∅1.6 7×7 $7.00/9.0 ft WRL w/pear end

B6 610-03120 ∅2.1 1×9 $1.30/ft stiff braid (brake)

B9-B18: Bulk Conduit

MM# 00 part# 0 OD x ID for

MM# 00 part# 0 OD x ID wire price /ft color

B9 610-03310 5.5 x 2.9 2.0 none /ft black

B10 610-03315 5.5 x 2.5 1.6 none /ft black, nylon-lined

B11 610-03320 6.0 x 3.3 2.5 $1.50/ft black

B12 610-03325 6.0 x 2.9 2.0 none /ft black, nylon-lined

B13 1460 0000 4.9 x 2.0 1.6 $0.60/ft black, nylon-lined

B14 1461 0000 4.9 x 2.0 1.6 $0.50/ft white, nylon-lined

B15 0000 0000 5.7 x 2.0 1.6 $0.50/ft brown lined, AMF ’80’s

B16 14427 000 4.8 x 2.0 1.6 $0.30/ft yellow

B17 14426 000 4.8 x 2.0 1.6 $0.30/ft blue

B18 14339 000 5.0 x 1.9 1.6 $0.80/ft light gray, nylon-lined

B20: Bulk Sleeve

B20 1508T32 big outer sleeve 11 x 13mm black PVC

holds three 5 mm cables $1.00/ft new and flexible