Contents

Contents

carburetor yrs mph Honda model

6. PA08B-A ’77-78 30 NC50 Express

6. PA08B-B ’77-79 30 NC50, NA50

6. PA08C-A ’78-79 30 NC50, NA50

6. PA08E-A ’80-80 30 NC50 Express

6. PA08E-B ’80-80 30 NC50 Express

6. PA08D-A ’80-80 30 NA50 Express II

7. PA12A-A ’81-81 30 NCZ50 Moto Compo

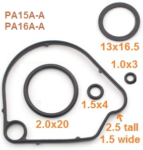

7. PA15A-A ’81-81 30 NC50 Express

7. PA16A-A ’81-81 30 NA50 Express II

7. PA13B-A ’81-82 30 NX50 Express SR

7. PA13B-B ‘82-83 30 NC50 Express

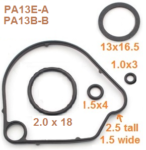

7. PA13E-A ’82-83 30 NU50 Urban Express

7. PA25A-A ’82-83 25 NC50I Express (Iowa)

6. Keihin

# size carb code mph from frame # US model

a 12 PA08B-A 147 30 NC50-1139281 ’77 NC50 Express

a 12 PA08B-A 147 30 NC50-2000013 ’78 NC50 Express

b 12 PA08B-B 147 30 NC50-1139281 ’77 NC50 Express

b 12 PA08B-B 147 30 NC50-2000013 ’78 NC50 Express

b 12 PA08B-B 163 30 AB01-5000001 ’79 NA50 Express II

c 12 PA08E-A 147 30 NC50-2100011 ’79 NC50 Express

c 12 PA08E-A 147 30 NC50-2200005 ’80 NC50 Express

d 12 PA08E-B 147 30 NC50-2100011 ’79 NC50 Express

d 12 PA08E-A 147 30 NC50-2200005 ’80 NC50 Express

e 12 PA08D-A 163 30 AB01-5200001 ’80 NA50 Express II

1. ’77 NC50, 2. ’78 NC50, 3. ’79 NC50, 4. ’80 NC50, 5. ’80 NA50

1. 16100-147-675 Keihin PA08B-A

2. 16100-147-676 Keihin PA08B-B

3. 16100-147-711 Keihin PA08E-A

1. 16100-147-712 Keihin PA08E-B

2. 16100-163-771 Keihin PA08D-A

3. Honda Express carburetor versions

Flange Mount: 38 mm hole spacing. 2 x 20 (24 od) intake o-ring.

Cable choke: This carburetor has a throttle cable and a choke cable coming straight up and looping around. It has no vent hoses, vacuum hoses, or oil lines going into it. The oil injection goes into the intake manifold. The float reservoir vent is just a small tube slanting downward.

As with most Honda carburetors, fuel is never allowed to spill onto the engine or anything else. Instead an overflow tube inside the float chamber allows any overflow fuel to flow out and down the drain hose and onto the ground below the engine.

The 1977-79 Honda NC50 and NA50 each had two carburetor versions, PA08B-A and PA08B-B. Regardless of the year, or the VIN number, they could have either version. So the customer had to look at the model number stamped into the carburetor, and tell the Honda dealer that number, to get certain parts correct.

Oil injection hose location: The 1977-79 Honda Express had the oil hose going into the intake manifold, not the carburetor. The 1980 and later models had the oil injection hose going into the carburetor at the throttle slide area. There must have been some benefit, like maybe throttle slide lubrication.

1. 16010-143-620, 2. 16010-143-305, 3. 16010-147-004

4. 16010-147-711, 5. 16010-147-505

o# abcde price Honda part# carburetor

10 10000 N/A 16100-147-673

10 10000 N/A 16100-147-675 PA 08B-A 77-79 NC50

10 01000 N/A 16100-147-676 PA 08B-B 77-79 NC50 NA50

10 00100 N/A 16100-147-711 PA 08E-A 1980 NC50

10 00010 N/A 16100-147-712 PA 08E-B 1980 NC50

10 00001 N/A 16100-163-771 PA 08D-A 1980 NA50

o# abcde price Honda part# parts list

o1 10000 $35 16010-143-620 gasket solo-set 1a o c d f g o i s

o1 10000 $37 16010-143-305 gasket multi-set 1a o c d f g h i s

o1 01010 $30 16010-147-004 gasket solo-set oo b c o f g

o1 01111 $30 16010-147-711 gasket solo-set oo b c d f g

o1 01111 $31 16010-147-505 gasket multi-set oo b c d f g o i

1a 10000 $$3 00000-000-000 top rubber washer 10 x 18.5 x 1

1b 01111 $$8 00000-000-000 top rubber washer 13 x 16.5 x 1

1c 11111 $$2 00000-000-000 intake o-ring 2 x 20 (24 od)

1d 11011 0$2 16176-551-004 jet or screw o-ring 1 x 3 (5 od)

1s 11000 $14 00000-000-000 jet support pad disk Ø7.3 x 1.85

1f 11111 $18 00000-000-000 float bowl gasket Ø1.5 NC50-type

1g 11111 $$2 00000-000-000 drain plug o-ring 1.5 x 4 (7 od)

o2 10010 N/A 16011-881-741 float needle valve stirrup

o2 10010 $36 16011-881-741 float needle genuine stirrup

o2 01101 $22 16155-883-005 float needle valve regular

o3 10100 N/A 16012-147-004 needle set 3a 3b 3c 3e 08B-A,E-A

o3 01011 $15 16012-147-014 needle set 3a 3b 3c 08B-B,E-B,D-A

o3 00000 $22 16012-130-640 needle set 3a 3b 3c 3e PA 03A-A

o3 00000 $22 16012-165-014 needle set 3a 3b 3c 3e PA 03B-A

3a 11111 0$5 16156-044-004 jet needle w-clip

3b 11111 0$2 16157-044-004 jet needle e-clip 1.5 for Ø2.0 needle

3c 11111 $10 00000-000-000 jet needle Ø2.0 D348 08B-A,B,03A,00A,01A

3d 00000 $10 00000-000-000 jet needle Ø2.0 D117 thin 03B,C,D,H-B,M-A

3e 10100 N/A 00000-000-000 needle jet (length 26.5) 08BA 08EA

3f 01011 N/A 00000-000-000 needle jet & jet fixed 08B-B, E-B, D-A

3g 00000 $10 00000-000-000 needle jet (emulsion tube) PA 03A-A

3h 00000 $10 00000-000-000 needle jet (emulsion tube) PA 03B-A

04 10010 N/A 16013-143-620

04 10010 $46 16013-099-691 float set 4a oo 4c 4d black stirrup

04 01101 $28 16013-147-004 float set oo 4b 4c 4d white regular

4a 10010 N/A 00000-000-000 float bare, solid black foam stirrup

4b 01101 $21 00000-000-000 float bare hollow white plastic regular

4c 11111 $$4 00000-000-000 hinge pin substitute Ø2 x 18.5

4d 11111 $$3 0-93600-04006 hinge screw M4x6 sunk phillips

05 10000 $29 16014-143-620 top set 5a 1a M20-1.0

05 01111 $36 16014-147-004 top set 5a 1b M18-1.0

06 10000 N/A 16015-147-004 chamber set A 6a oo 6c 1e 1f 1g for jet pad

o6 01111 N/A 16015-147-014 chamber set B oo 6b 6c oo 1f 1g for no pad

6a 10000 N/A 16015-147-004 float bowl A shallow with pad holder

6b 01111 N/A 16015-147-014 float bowl B shallow, no jet pad holder

6c 11111 $16 00000-000-000 float drain screw M6x20 special

o7 11010 $21 16016-143-620 screw set 7a b c d idle air

o7 00101 N/A 16016-147-711 screw set 7a b o d e f g idle fuel

7a 11111 $$4 00000-000-000 idle speed screw M4x19 special

7b 11111 $$2 00000-000-000 idle speed screw spring Ø5.6 x 10

7c 11010 $$9 00000-000-000 idle air screw M6-0.75 thick tip

7d 11111 $$7 00000-000-000 idle air or fuel spring Ø4.8 x 9

7e 00101 $12 00000-000-000 idle fuel screw M6-0.75 thin tip

7f 00101 $$7 00000-000-000 idle fuel screw washer 3.1 x 5.0 x 0.5

7g 00101 0$2 16176-551-004 idle fuel screw o-ring 1 x 3 (5 od)

o8 11111 $38 16022-143-620 valve set 8a, 8b

8a 11111 $22 00000-000-000 throttle slide Ø13 #15A

8b 11111 $12 00000-000-000 throttle spring original Ø9.5 x 42

8b 11111 $$7 00000-000-000 throttle spring substitute shorter, stiffer

o9 11111 $25 16046-147-004 choke set substitute 9a 9b 9c

9a 11111 $15 00000-000-000 choke top substitute M12-1.0

9b 11111 $$4 00000-000-000 choke spring substitute

9c 11111 $12 00000-000-000 choke slide substitute

11 11111 0$2 16118-166-004 rubber boot substitute Dellorto

12 22222 $$1 0-93500-04012 bowl screw M4x12 pan phillips

13 22222 .40 0-94111-04000 lock washer M4 split

14 11111 0$1 0-95001-35003 hose substitute 1/8 x ¼ 3.1 x 6.3

15 11111 N/A 0-95002-02070 drain hose clamp B7 (for 7 not 6.3)

16 10000 N/A 99201.081.0780 push-in jet 78 08BA

16 10000 $23 substitute jet, #70 drilled to 78 08BA

16 01111 N/A fixed needle jet & jet pressed in 08BB EA EB DA

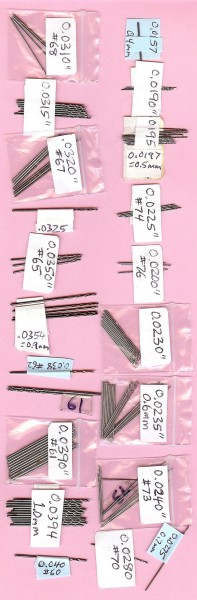

this jet is 0.78mm 0.0307″, cleaned with a #69 drill 0.0292″

00 22222 $1.00 mount bolt, nut and washer M6 x 20

1. ’77-79 NC50 idle screws: 7a idle speed, tighter is faster, 7c idle air mix, tighter is richer

2. ’80-83 NC50 idle screws: 7a idle speed, tighter is faster, 7e idle fuel mix, tighter is leaner

Float: The white float with non-stirrip needle for PA08B-B and the black float with stirrup type needle for PA08B-A do not interchange. The white float is too “tight” on the PA08B-A. Something restricts its movement. The black float is too “loose” on the PA08B-B. It moves a lot before moving the needle.

Main Jet: On PA08BB, EA, EB and DA versions the main jet is a tamper-proof tight press-fit type, in the center. The jet cannot be removed, and cannot be replaced. It is 0.78 mm – 0.0307″, and can be cleaned perfectly with a #69 drill 0.0292″.

On a PA08BA the main jet presses or slides in and out, and is supported by a rubber disk. If the disk is missing, the jet can slide downward, allowing fuel to get past the jet o-ring, causing a rich fuel mixture.

Idle Hole Cleaning: Near the engine side of the carb body is a brass tube that dips down into the liquid gasoline. That tube, about 1.5 mm (0.060″) inner diameter and 20mm long, leads to the idle or pilot jet, which is about 0.30 mm (0.012″). The idle jet gets clogged from sitting, then the engine will run but won’t idle. Nothing but a very thin (0.010″) steel guitar string will clean it out. See below about jet drills and cleaning tiny jets. Ultrasonic parts cleaners, carb spray, carb dip, and compressed air are not usually effective. Another way to clean out the idle jet is to 1) place a drill bit that fills the hole (so it does not get crushed), 2) clamp it with a small vise grips, 3) rotate back and forth while pulling, 4) when it comes out, the actual hole is easy to see and clean, 5) press it back in the same way it came out.

Strong solvent is needed to dissolve varnish or tar residue left from years of sitting. Carburetor spray, parts dip, or acetone all help clean out the tar, sometimes with a lot of scraping, brushing or rubbing. Always remember to remove all rubber things first, to not let the rubber touch the solvent. Strong solvents will swell soft rubber, deforming it. Never soak the whole carburetor in strong solvent. In this way, Shaun (at Royal Cyclery and later at Myrons Mopeds) has successfully cleaned out over 100 Honda Express carburetors, without ever replacing any of the rubber gaskets. Part of the reason was they were only sold at Honda dealers, but nonetheless, they are not needed in a normal service or clean-out.

Keihin PA08C-A: This is approximately for a 1979-80 NC50, or maybe NA50. It is identical to a PA08B-B. It has the same white float, non-stirrup float needle, fixed jet, 18mm top threads, and same gaskets. The idle mixture screw type is unknown. No photo available.

7. Keihin

# size carb code mph years Honda models

a 12 PA12A-A GC6 30 ’81-81 NCZ50 Moto Compo

b 12 PA15A-A 190 30 ’81-81 NC50 Express (US)

c 12 PA16A-A 193 30 ’81-81 NA50 Express II (US)

d 12 PA13B-A 187 30 ’81-82 NX50 Express SR (US)

e 12 PA13B-B GC1 30 ’82-83 NC50 Express (US)

f 11 PA25A-A GA6 25 ’82-83 NC50I Express (Iowa)

g 12 PA13E-B GC1 30 ’82-83 NU50 Urban Express (US)

e 12 PA13B-B GC1 30 ’82-83 NU50M U. Exp. Deluxe (US)

1. ’81 NC50 Express, 2. ’81 NA50 Express II, 3. ’81 NX50, 4. ’82 NU50

a. PA12A-A, b. PA15A-A, c. PA16A-A, d. PA13B-A

e. PA13B-B, f. PA25A-A, g. PA13E-A

Flange Mount: 38 mm hole spacing PA15A-A, PA16A-A, PA13B-B

Flange Mount: 32 mm stud spacing PA13B-A, PA13E-A

Flange Mount: 36 mm hole spacing PA25A-A

Vacuum-operated automatic choke: Except for PA12A-A which has a cable-operated choke, these carburetors feature a vacuum-operated (not electric) automatic choke. When the temperature switch on the head is cold, it allows the engine vacuum to raise the choke plunger up, which opens a new fuel passage, to enrich the mixture during cold starting. As the engine warms up, it closes the vacuum, allowing the thin spring to pull it back down, for normal running. The more precise term for this is “automatic vacuum operated cold start fuel mixture enrichment device”. The 1981-83 automatic choke device itself is not replaceable.

The vacuum source hose has a check ball valve that only allows air flow into the carburetor venturi, and not back out. It needs this even though there is reed valve, because there is still some residual reverse flow caused by the forward and reverse motion of the piston.

The vacuum choke that came out in 1981 did not last long. After 1983, 50cc on-road Honda’s had electric chokes, because they were electric-start scooters with 12 volt batteries.

Identical twins: The PA16A-A looks identical to the PA15A-A. It is on the 1981 Honda NA50 Express II, the final year of that USA-only model. They both have 38 mm flange hole spacing, #75 screw-in jet, 20 mm intake o-ring and the non-stirrup type B float needle. The only difference is the top cable curved pipe. On a PA15A-A it is permanently attached to the screw-on top cap with a swivel joint, while on a PA16A-A the curved cable pipe is detachable.

Intake studs: After 1981 these carbs had studs instead of threaded holes in the mounting flange, except for PA25A-A. PA13B-A and PA13E-A studs are spaced 32 mm with a 18mm intake o-ring. PA13B-B studs are spaced 38 mm, with a intake o-ring 20 mm.

Iowa carb: The PA25A-A is like a PA13B-A, with M18-1.0 top cap threads, 13.0 mm slide, vacuum-operated automatic choke, choke jet in float bowl, tall 2.5 x 1.5 float bowl gasket, intake o-ring 20 mm, 38mm mount spacing, non-stirrup type float and float needle, screw-in main jet size 75. The only noticeable difference is the absence of studs.

Iowa cylinder: The exhaust port is restricted. Here left is 49-state, right is Iowa.

Keihin PA12A-A: This carb from a NCZ-50 has a cable choke like the ’77-79 NC50 carbs. But it has a different part number, 16046-GC6-003 instead of 16046-147-004. Despite that, the NC50 replacement cable choke top and choke pieces fit the NCZ50.

1. 16010-190-004 for 15A 16A 13BB 25A

2. 16010-187-003 for 12A 13BA 13EA

3. 16010-GF8-305 for PA 13BA 13EA

o# abcde f g price Honda part# carburetor .

00 1o00000 N/A 16100-GC6-003 PA12A-A ’81-81 NCZ50

00 01o0000 N/A 16100-190 -672 PA15A-A ’81-81 NC50

00 0010000 N/A 16100-193 -672 PA16A-A ’81-81 NA50

00 0001000 N/A 16100-187 -673 PA13B-A ’81-82 NX50

00 0000100 N/A 16100-GA6-671 PA13B-B ’82-83 NC50

00 0000010 N/A 16100-GA6-671 PA25A-A ’82-83 NC50I

00 0000001 N/A 16100-GC1-671 PA13E-A ’82-83 NU50

o# abcde f g price Honda part# parts list .

01 1001001 $24 16010-187-003 gasket solo-set 1b o d g h k

01 0110110 $24 16010-190-004 gasket solo-set 1b c d g o k

01 1001001 $32 16010-GF8-305 gasket multi-set 1b o d g h k t u

1b 1111111 $$8 00000-000-000 top rubber washer 13 x 16.5 x 1

1c 0110110 $$2 00000-000-000 intake o-ring 2 x 20 (24 od)

1d 1111111 0$2 16176-551-004 idle fuel screw o-ring 1 x 3 (5 od)

1g 1111111 $$2 00000-000-000 drain plug o-ring 1.5 x 4 (7 od)

1h 1001001 $$2 00000-000-000 intake o-ring 2 x 18 (22 od)

1k 1111111 $22 00000-000-000 float bowl gasket 2.5 tall by 1.5 wide

02 00010?0 N/A 16012-187-671 needle set ’81 2a 2b 2c 2d

02 0001000 N/A 16012-187-731 needle set ’82 2a 2b 2c 2d

02 01100?0 N/A 16012-193-671 needle set 2a 2b 2c 2d

02 ?0001?1 N/A 16012-GA6-671 needle set 2a 2b 2c oo 2e

02 ?0000?1 N/A 16012-GC1-671 needle set 2a 2b 2c oo 2f

2a 1111111 0$5 16156-044-004 jet needle w-clip

2b 1111111 0$2 16157-044-004 jet needle e-clip for 1.5 clip groove

03 1111111 $28 16013-147-004 float set white 3a 3b 3c

3a 1111111 $21 00000-000-000 float bare white plastic regular

3b 1111111 $$4 00000-000-000 hinge pin substitute Ø2 x 18.5

3c 1111111 $$3 0-93600-04006 hinge screw M4x6 sunk phillips

04 1000000 N/A 16014-GC6-003 top set NCZ50 no cable pipe M18-1.0

04 0100000 N/A 16014-190-014 top set NC50 fixed cable pipe M18-1.0

04 0010000 $36 16014-147-014 top set NA50 M18-1.0

04 0001110 N/A 16014-187-013 top set NX50, 82-83 NC50 M18-1.0

04 0000001 N/A 16014-GB2-003

04 0000001 N/A 16014-GB0-831

04 0000001 N/A 16014-098-980 top set NU50 fixed cable pipe M18-1.0

05 1000000 N/A 16015-GC6-003 chamber set

05 0110000 N/A 16015-191-034 chamber set deep bowl with choke jet

05 0001000 N/A 16015-187-671 chamber set deep bowl with choke jet

05 00001?0 N/A 16015-GA6-671 chamber set deep bowl with choke jet

05 00000?1 N/A 16015-187-043 chamber set deep bowl with choke jet

06 1000111 $32 16016-191-004 idle fuel screw set 6 6b 6f 1d

06 0111000 $32 16016-187-003 idle fuel screw set 6 6b 6f 1d

6e 0111000 $12 00000-000-000 idle fuel mixture screw M6-0.75 special

6b 1111111 $$7 00000-000-000 idle fuel mix screw spring Ø5 x 9

6f 1111111 $$7 00000-000-000 idle fuel mix screw washer 3.1×5.0x0.5

07 1111111 $00 16028-187-003

07 1111111 $21 16028-GC8-004 idle speed screw and spring 7a 7b

7a 1111111 $$4 00000-000-000 idle speed screw M4x19 special

7b 1111111 $$2 00000-000-000 idle speed screw spring Ø5.5×10

08 1000000 $38 16022-081-004 throttle slide & spring

08 0110000 $38 16022-143-620 throttle slide & spring

08 0001010 N/A 16022-187-731 throttle slide & spring

08 0000101 N/A 16022-191-004 throttle slide & spring

8a ?11?? 1? $22 00000-000-000 throttle slide Ø13 #15A

8b ?11?? 1? $12 00000-000-000 throttle slide spring Ø9.5 x 42

10 1100000 N/A 16118-086-004

10 1100000 N/A 16118-166-004 cable rubber boot

10 0001110 N/A 16118-187-003 cable rubber boot

10 0000001 N/A 16118-GB4-003 cable rubber boot

11 1111111 $22 16155-883-005 float needle valve KL 18-4608

12 1000000 N/A 16199-GC6-003 overflow hose 3.0 x ??

12 0110110 N/A 16199-435-771 overflow hose 3.0 x 6.5

12 0001001 N/A 16199-187-003

12 0001001 N/A 16198-HC0-405 overflow hose 3.0 x 6.5

13 0001000 N/A 16608-187-000 control hose with check ball 5 x 10

13 0110000 N/A 16608-193-670 control hose with check ball 5 x 10

13 0000110 N/A 16608-GA6-670 control hose with check ball 5 x 8

13 0000001 N/A 16608-GC1-000 control hose with check ball 5 x 8

14 2222222 0$1 93892-04012-8 screw & washer M4x12 pan phillips

15 0111111 N/A 0-95002-02070 hose clamp B7 vacuum source hose

16 0111000 N/A 0-95002-02100 hose clamp B10 for control hose

16 0000111 N/A 0-95002-02080 hose clamp B8 for control hose

17 1111111 N/A 0-95002-02650 hose clamp B6.5 for overflow hose

18 1111111 N/A 0-95005-35001 vacuum (source) hose 3.5 x 7 x 130

o# abcde f g price Honda part# screw-in jets M6-0.75 .

19 0000010 $$7 99101-187-0700 #70 PAMOA PA25A

19 0110100 0$7 99101-187-0750 #75 PA15A 16A 13BB

19 0001000 0$7 99101-187-0780 #78 PA13BA

19 1000000 0$7 99101-187-0800 #80 PA12AA

19 0000001 0$7 99101-187-0850 #85 PA13EA

1. idle fuel screw: top-original, bottom-replacement

2. 1982-83 NC50 hoses

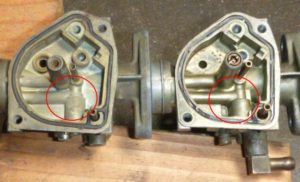

3. Keihin idle mixture screw channels: Left PA08B-B with idle air screw, Right PA15A-A with idle fuel screw. You can tell the difference between a carb with an idle air mixture screw, and a carb with an idle fuel mixture screw, by the shape of the casting at the top of the float chamber.

Float Valve Seat: On these carburetors the float seat (the cup that the float needle valve slides in) is carved into the actual carburetor body, and is not replaceable. Polish it with a spinning Q-tip and polish, such as Turtle Wax.

Choke jet: On all of these NC50-type carbs, both shallow and deep-float-bowl versions, there is a choke jet, pressed into a corner of the float bowl. When it gets clogged the engine will only start easily when it is warm.

Verify all jets and fuel or air passageways are open, using wires and or visually with carb spray (wear goggles).

Cable Differences: You can tell what year range a Honda Express is from a distance. A 1977 to 1980 has two cables, a throttle and a choke cable coming straight up from the carburetor. A 1981 has just a throttle cable coming straight up, but also a vacuum hose for the choke and a float vent hose. A 1982 to 1983 has a black plastic curved elbow on top, that redirects the throttle cable forward and down, a vacuum hose for the choke, and a vent hose. A 1982-83 also has a different frame, a low headlight, and a two speed transmission.

The Honda Express throttle cable curves rearward and loops downward to get below the carburetor, and then goes forward into the frame tube. The loop design adds friction, but it makes a good clean step-thru frame without any cables or wires hanging out.

Comparison of PA MOA-A, PA 08B-B, PA 08B-A, and PA 15A-A