Contents:

1. A-type on Tomos

2. S-type on Batavus, others

3. H-type on Trac, others

Part# colors: Tomos, Laura, Batavus, Trac, other

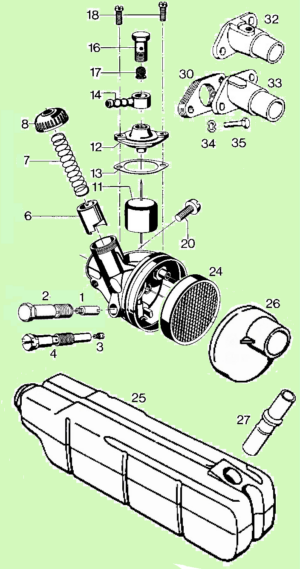

1. Encarwi A-type: A11, A21, A22

A83, 88A85/102, 88A85/103

– On some early-70’s Laura M48 engines.

– and ’74-85 Tomos A3 mopeds.

– Serviceable from sides.

– No choke cable. Choke is part of throttle.

# part# price Encarwi A-type on Laura M48 .

00 481780 none carburetor A11 ∅8? 1970?-

00 slide ∅14? 408, jet M3.5 52-54 M48-01 40kmh

00 481788 none carburetor A21 ∅12 1972?-

00 slide ∅14 202, jet M3.5 56-58 M48-02 50kmh

00 481789 none carburetor A22 ∅8? 1972?-

00 slide ∅14? 108, jet M3.5 50-52 M48-03 30kmh

# part# price Encarwi A-type on Tomos A3 .

00 209070 none carburetor A83 ∅12 1974-76

00 slide ∅14 426, jet M3.5×15 46 Tomos A3 20,25,30

00 209070 none carburetor A83 ∅12 1977-83

00 slide ∅14 426, jet M3.5 x 6 46 Tomos A3 20,25,30

00 209070 none carb 88A85/102 ∅12 1980-84

00 slide ∅14 426, jet M3.5 x 6 46 Tomos A3 20,25,30

00 209616 none carb 88A85/103 ∅12 1984-85

00 slide ∅14 426, jet M4.0 x 7 50 Tomos A3 20,25,30

01 long jets, thread 3.5, head 12, length 15:

01 481723 $12.0 orig. long jet =Bing45 0.434 mm

01 481724 $15.0 orig. long jet =Bing46 0.445 mm

02 481731 $20.0 long holder for long Encarwi 3.5 jet

03 short jets, thread 3.5, head 3, length 6:

03 209116 $18.0 orig short jet =Bing46 0.445

04 206765 $41.0 long holder for short Bing jet

06 209118 $18.0 slide Ø14 426 with hole, auto-choke

07 209003 $5.00 spring Ø9.5 x 42

08 206763 $34.0 carb top screw-on M18x1 thread

11 206770 $35.0 float with needle used only

12 206772 $25.0 float top with seat new

13 206771 $6.00 gasket for float top

14 206773 $15.0 banjo black plastic breaks easy

14 mbanjo $12.0 banjo metal upgrade w/2 washers

16 206775 $7.00 banjo bolt

17 206774 $15.0 fuel filter all metal clean & reuse

18 027053 $1.30 screw M4 x 10 slot

20 027079 $5.00 clamp bolt

24 200384 none air filter metal mesh

25 209215 $20.0 air box (silencer)

26 209216 $27.0 junction sleeve rubber, gets hard

27 209217 $3.00 inlet tube connector

28 209579 $3.00 inlet tube (not shown)

30 200382 $8.00 intake gasket thick

32 217315 none intake manifold oil inj w/M6x1 hole

33 209085 $22.0 intake manifold OD 16, ID 12

34 031932 $0.25 lock washer M6

35 044284 $1.00 hex bolt M6 x 22

Left, 1974-83 Tomos carb, Encarwi A83, bare.

The jet and jet holder unscrew from the side hole.

The jet can be cleaned out easy, on the roadside.

Right, 84-86 Tomos, Encarwi 88A85/103, complete.

The side hole is blocked. Jet access is from bottom.

The engine must be lowered to access the jet.

Jetting/servicing is ten times more difficult.

Here is a 88A85/103 with the non-removable jet-holder-spray-tube removed. The #50 jet is a 4mm thread, not 3.5 like all the other Encarwi jets. This one was not a tight fit and needed epoxy to hold it. When the jet was unscrewed the whole brass tube turned.

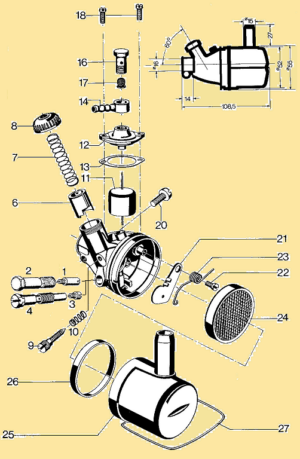

2. Encarwi S-type

S8A, S22, S23, S23A, S23B, 88S23/103,

S25, 88S25/101, S33, S33A

– On some early-70’s Laura M48 engines

– and 1974-80 Batavus, 1977-78 Badger.

– Located behind and below engine.

– Needs longer throttle and choke cables.

# part# price Encarwi S-type on Laura M48

00 487180 none carburetor S22 ∅12 30mph ’72-77

00 slide ∅14 405, jet M3.5×15 54-58, inlet ∅16 45-50kmh

00 541780 none carburetor S25 ∅12 30mph ’77-78

00 slide ∅14 167, jet M3.5 x 6 56-58, inlet ∅16 45-50kmh

00 541780 none carb 88S25/101 ∅12 30mph ’78-80

00 slide ∅14 188, jet M3.5 x 6 56-56, air inlet ∅16 50kmh

00 481790 none carburetor S8A ∅8 25mph ’72-80

00 slide ∅14 190, jet M3.5×15 52-54, air inlet ∅14 40kmh

00 486795 none carburetor S23A ∅8 20mph ’75-80

00 slide ∅14 190, jet M3.5 x 6 50-52, air inlet ∅14 30kmh

00 481795 none carburetor S23B ∅8 00mph ’75-on

00 slide ∅14 190, jet M3.5 x 6 52-54, air inlet ∅14 25kmh

00 481795 none carburetor S23 ∅8 00mph ’72-75?

00 slide ∅14 190, jet M3.5×15 50-52, air inlet ∅14 30kmh

00 486785 none carb 88S23/103 ∅8 00mph ’77-on

00 slide ∅14 190, jet with holder 54, air inlet ∅14 20kmh

# part# price Encarwi S-type on Flandria

00 000000 none carburetor S33 ∅12 00mph ’72-77

00 slide ∅14 000, jet M3.5×15 52-54, inlet ∅00 40kmh

00 000000 none carburetor S33A ∅12 25/30 ’76-77

00 slide ∅14 000, jet M3.5 x 6 52-54, inlet ∅00 40kmh

01 long jets, thread 3.5, head 12, length 15:

01 481723 $12.0 orig. long jet =Bing45 0.434 mm

01 481724 $15.0 orig. long jet =Bing46 0.445 mm

01 481726 none orig. long jet =Bing50 0.478 mm

01 481727 none orig. long jet =Bing52 0.493 25mph

01 481729 none orig. long jet =Bing56 0.523 30mph

01 481730 $7.00 orig. long jet =Bing58 0.541 mm

02 481731 $20.0 long holder for long Encarwi jet

03 short jets, thread 3.5, head 3, length 6:

03 486750 none orig. short jet =Bing50 0.478 20mph

03 bing51g $4.00 generic48 jet ≈Bing51 0.480 mm

03 bing52g none generic49 jet ≈Bing52 0.490 mm

03 486752 $5.00 orig. short jet =Bing52 0.493 25mph

03 bing53g $4.00 generic50 jet ≈Bing53 0.500 mm

03 486754 $5.00 orig. short jet =Bing54 0.508

03 bing56g $4.00 generic52 jet ≈Bing56 0.520 mm

03 486756 $11.0 orig. short jet =Bing56 0.523 30mph

04 481722 $41.0 long holder for short Bing jet

06 481758 none throttle slide #405 S22 30mph

06 561742 $35.0 throttle slide #167 S25 30mph

06 5617xx none throttle slide #188 88S25/101

06 486723 none throttle slide #190 25 & 20mph

07 481722 $5.00 spring Ø9.5 x 42

08 481721 $34.0 carb top screw-on M18x1 thread

09 481746 $12.0 idle screw M4-0.7 can use M4

10 481747 $3.00 spring Ø4.6 Ø6.6 x 9

11 481736 $35.0 float with needle used only

12 481738 $25.0 float top with seat

13 481737 $6.00 gasket for float top

14 481740 $15.0 banjo black plastic

14 mbanjo $12.0 banjo metal upgrade w/2 washers

16 481742 $7.00 banjo bolt

17 481741 $15.0 fuel filter

18 481739 $1.30 screw M4 x 10 slot

20 481724 $5.00 clamp bolt

21 481743 $7.00 choke plate

22 481745 $3.00 bolt choke pivot

23 481744 $3.00 spring choke

24 481732 none air filter metal mesh

25 481713 none air box (13.5id, 16od) N/A 30mph

25 481734 none air box (11.5id, 14od) N/A 25/20mph

26 481733 none rubber band N/A

27 481735 $8.00 wire clip

28 481793 none intake tube 16 id N/A 30mph

28 486781 $5.00 intake tube 14 id 25 & 20mph

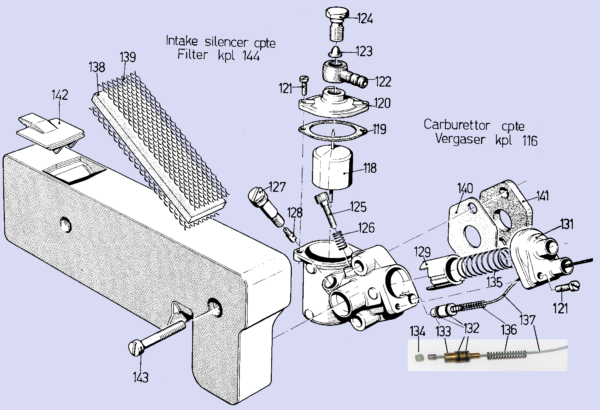

3. Encarwi H-type: H12, H8

– Made special for Laura M56 engine.

– Serviceable without removal.

– Used on 1978-80 Batavus Regency (M56)

– 1981-85 Trac Clipper, Eagle, Hawk (M56)

# qty part# price Encarwi H-type 1978-85

116 1 561782 $220. carburetor H12 ∅12 30, 25mph

116 1 561782 $000. slide ∅14, jet M3.5 56 .

116 1 561787 N/A carburetor H8 ∅8 20mph

116 1 561787 $000. slide ∅12?, jet M3.5 46 .

118 1 481736 $35.0 =206770 float with needle, good-used

119 1 481737 $6.00 =206771 gasket for float top

120 1 561741 $35.0 float top and seat no vent use 206772

120 1 206772 $25.0 float top and seat vented

121 3 481739 =027053 screw M4 x 15 slot

122 1 mbanjo $12.0 banjo metal with 2 washers

122 2 swash8 $1.00 banjo seal washer 8mm

123 1 481741 $15.0 =206774 fuel filter

124 1 481742 $7.00 =206775 banjo bolt

125 1 561740 $5.00 idle screw M5-0.80 x 16

126 1 481747 $2.00 spring idle screw Ø5,Ø7 x 10

127 1 082510 $40.0 short holder for short Bing jet

127 1 491722 $30.0 short holder for medium Encarwi jet

128 short jets, thread 3.5, head 3, length 6:

128 1 486746 $18.0 orig. short jet #46 =0.445 mm

128 1 486756 $11.0 orig. short jet #56 =0.523 mm

128 1 486756 $4.00 generic subst #52 =0.520 mm

128 1 486756 none generic subst #53 =0.530 mm

128 medium jets, thread 3.5, head 8, length 11:

128 1 566756 $12.0 orig medium jet 56 =0.523 mm

128 1 566746 N/A orig medium jet 46 =0.445 mm

129 1 561748 $25.0 slide throttle Ø14 (H12) #3

129 1 561742 N/A slide throttle Ø12? (H8)

130 1 046430 $7.00 rubber cover over carb top

131 1 561721 $25.0 carb top white plastic

132 2 561745 $2.00 o-ring for choke 1 x 4.0

133 1 561743 N/A choke slide

134 1 561743 N/A choke slide set screw M4

135 1 481759 $10.0 spring throttle Ø9.5 x 44

136 1 491724 $8.00 spring choke return

137 1 561747 choke cable wire only

138 1 561713 $5.00 air filter foam strip

139 2 561714 N/A air filter screen

140 1 561747 $52.0 choke cable assy 132,133,134,136,137

143 1 823514 $0.70 screw M5 x 30 phillips

144 1 561795 N/A air box with filter good used

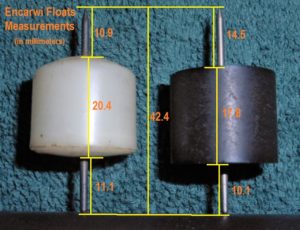

Encarwi Jets: Most Encarwi carburetors use standard Bing 3.5mm jets. Those jets have a “short” head that is only 3mm long. To use a short jet, the jet holder must be for a short jet. But some Encarwi carburetors have longer 3.5mm jets with 8mm “medium” or 12mm “long” heads.

Encarwi jet holders

1 481722 long jet holder for short (Bing) jet

2 481731 long jet holder for long Encarwi jet can be a substitute for 3

3 491722 short jet holder for medium Encarwi jet

4 082510 short jet holder for short (Bing) jet